Fundamentals of Strength of Materials: An In-Depth Exploration

Abstract: This article provides a comprehensive understanding of the primary principles underlying the strength of materials, a fundamental area of study within the broad domain of engineering mechanics. We will explore key concepts such as stress, strain, elasticity, and plasticity, which are critical in predicting the behavior of materials under different loading conditions. This understanding aids in the design of structures and materials that can sustain applied forces and environmental conditions without failure.

Keywords: Strength of Materials, Stress, Strain, Elasticity, Plasticity, Mechanical Properties

- Introduction

Strength of Materials, also known as Mechanics of Materials, is a core discipline in mechanical, civil, and aerospace engineering that investigates the response of solid objects to stresses and strains. It serves as the foundation for designing structures and material components that can withstand applied loads without failing or deforming excessively. It aids in assessing the load-bearing capacity, toughness, ductility, and durability of materials.

- Stress

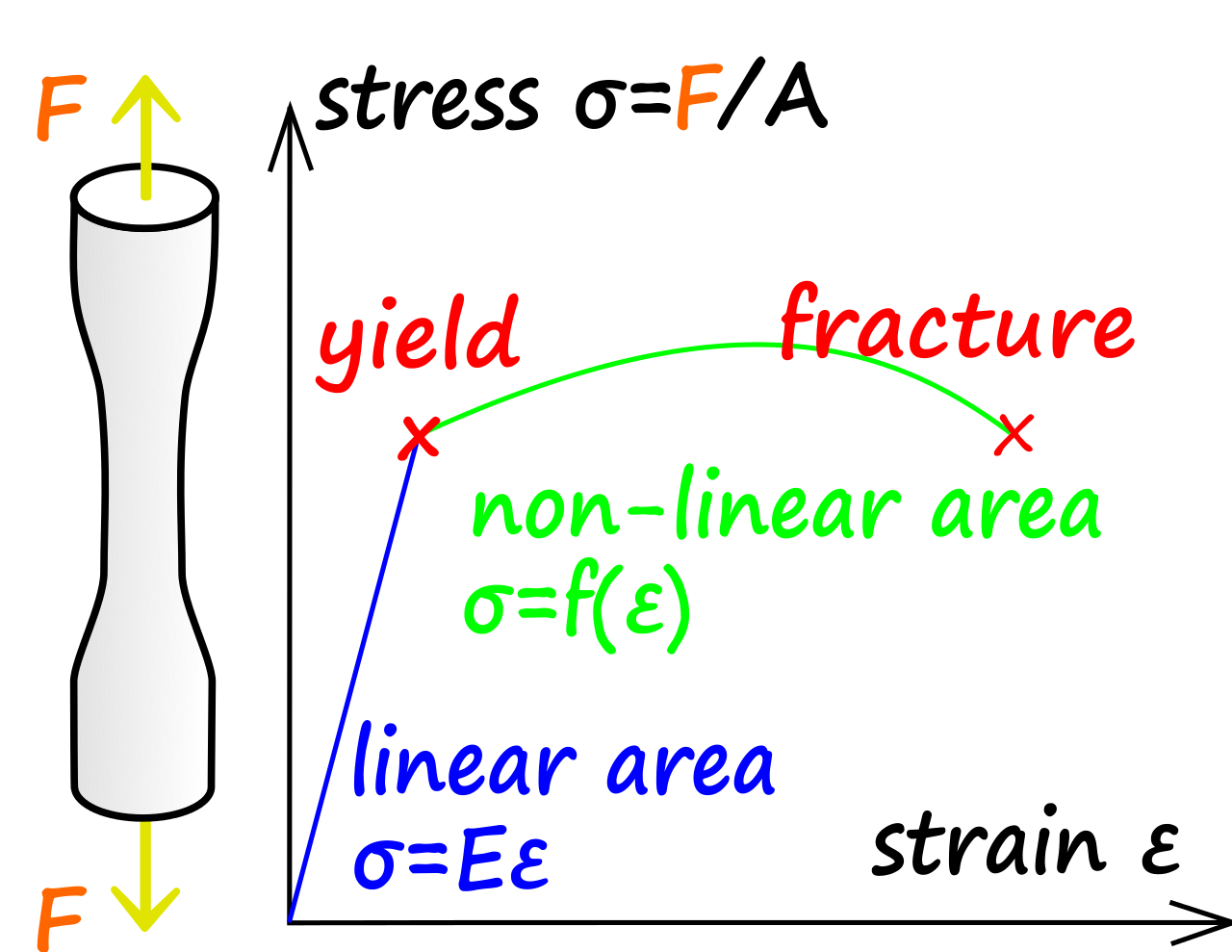

Stress, represented by the Greek letter σ (sigma), is the internal resistance offered by a material to an externally applied force. It is a measure of the intensity of the internal forces within a material and is defined as the force (F) applied per unit area (A). Mathematically, σ = F/A. Depending upon the nature of the applied force, stress can be classified into three primary types: tensile, compressive, and shear stress.

- Strain

Strain, represented by the Greek letter ε (epsilon), measures the deformation or displacement experienced by a material under stress. It is a dimensionless quantity defined as the change in length (ΔL) divided by the original length (L). Strain can be expressed as ε = ΔL/L. Like stress, strain also manifests in various forms, including tensile, compressive, and shear strain.

- Elasticity

Elasticity is a material's property to regain its original shape and size after the removal of stress. The elastic behavior of materials is governed by Hooke’s Law, which states that the stress induced in a material is directly proportional to the strain, provided the stress is within the material's elastic limit. The constant of proportionality is known as the modulus of elasticity or Young's modulus (E). It is given by the ratio of stress to strain: E = σ/ε.

- Plasticity

In contrast to elasticity, plasticity is the property of a material that allows it to deform permanently under stress without breaking. This phenomenon occurs once the stress exceeds the elastic limit, causing irreversible deformation. Plastic behavior is essential in many manufacturing processes such as forging, extrusion, and rolling.

- Conclusion

Understanding the strength of materials and their response to stress and strain is crucial for the design and manufacture of durable, efficient, and safe products. Engineers must consider these principles when choosing materials and designing structures to ensure that they can withstand the intended loads and operating conditions. This field is continually evolving with the development of new materials and more sophisticated analysis methods, promising even greater innovations and applications in the future.